KeyCast Resin

Price

High-precision Casting Resin. Burns residue-free.

Description

KeyCast Resin

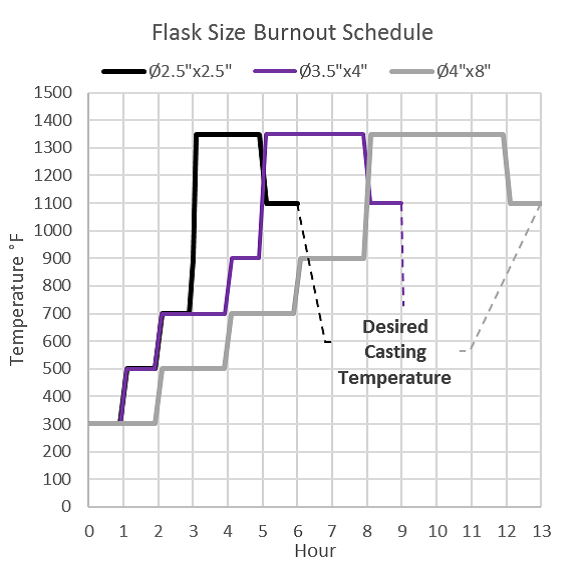

KeyCast Resin is compatible with rapid burnout and workflow using gradual temperature, without residual ash.

KeyCast is used with chrome, cobalt, gold, and silver.

The low shrinkage formula controls thermal expansion to achieve precise and pore-free casted parts.

Casting Procedure and Recommendations

For best results, Keystone recommends using Kerr’s “Satin Cast 20” or Ransom & Randolph’s “Ultra-Vest” investment materials. This will ensure there are no adverse reactions between the casted piece and the material during the burnout process.

For optimal results, the flasks should be vacuumed or centrifuged to remove any air bubbles. The flasks should be bench-set for 2 hours before exhausting.

Keystone recommends leaving more than 4mm of space between the edges of the pieces and the outer edge of the flask. This will ensure proper expansion absorption during the exhaust.

Note: It is extremely important to maintain the temperature ramp at 500°F (260°C) for at least one hour, depending on the flask size. This will ensure proper dimensional stability of the part.

Rating & Review

There are no reviews yet.